In the ever-evolving world of industrial automation, collaborative robots, known as cobots, are setting the stage for a seismic shift. By 2033, the global market for cobots is anticipated to soar to approximately $23.5 billion, reflecting their growing importance within the industry. As manufacturers seek to optimize workflows and reduce costs, cobots are becoming indispensable allies on production floors, working hand-in-hand with human counterparts.

The New Collaborative Workspace

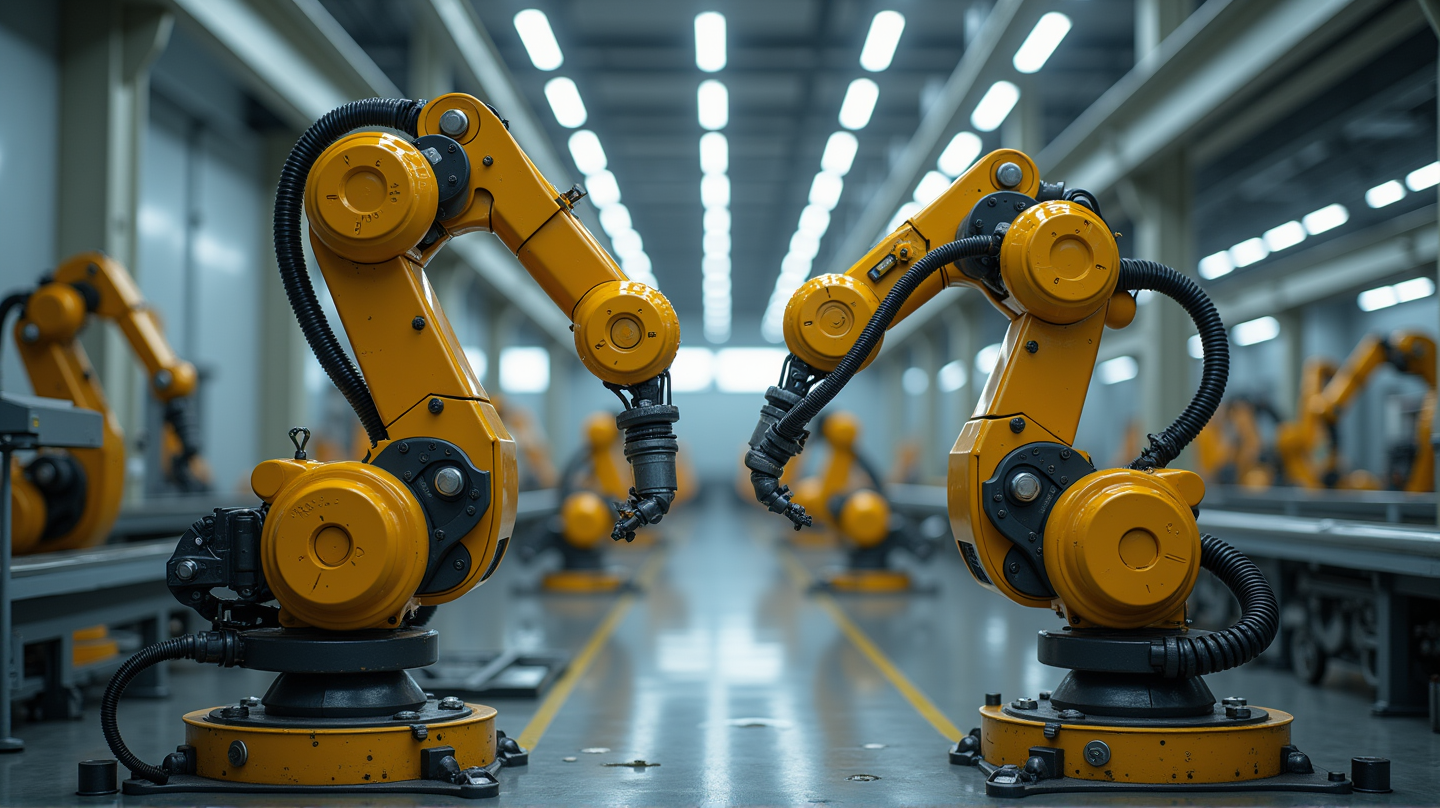

As stated in IOT Insider, robotics technology is driving the transition from isolated machine environments to collaborative spaces where humans and robots function side-by-side. Cobots streamline processes by taking on repetitive tasks, thus freeing human workers for more strategic roles that require creativity and innovation. It’s this synergy, where precision meets human intuition, that is reshaping manufacturing.

The Foundational Software Revolution

Crucial to the operation of these robots is the foundational software, providing stability, performance, and security. A robust operating system ensures that cobots maintain precise timing and control, safeguarding both human workers and product quality. By supporting machine learning and sensor technology, cobots can adapt to human interactions in real-time, creating seamless integration in production lines. This is not just a technological advancement; it heralds a new era of possibilities in industrial efficiency and safety.

Emphasizing Safety in Automation

With the rise of collaborative robots, the demand for enhanced functional safety has never been more critical. Advanced safety measures are fundamental to enabling cobots to operate in proximity to humans safely. These protocols not only protect workers and prevent accidents but also build trust in automation systems. By adhering to international safety standards like ISO 10218 and IEC 61508, manufacturers ensure their cobots are both reliable and safe.

Overcoming Challenges for Integration

While integrating cobots into existing infrastructure presents challenges, focusing on safe design, proper integration, and software compatibility can overcome these hurdles. The real benefit emerges when humans and robots collaborate, blending the meticulous accuracy of machines with the imaginative solutions of people. This partnership is not merely about efficiency; it symbolizes a transformative approach to manufacturing that enhances safety and productivity.

A Vision for the Future

The future of manufacturing is collaborative and interconnected, where cobots and humans complement each other’s strengths. This partnership not only enhances operational efficiency but also enriches job satisfaction by leveraging human creativity and problem-solving alongside robotic precision. As we embrace this new frontier, the promise of cobots lies in their ability to redefine the industrial landscape while keeping innovation and safety at the forefront.

As industries continue to innovate, the full potential of collaborative robots is yet to be realized, offering a promising horizon for both workers and enterprises. By embracing this technology, manufacturers stand to not only increase efficiency but also foster a more engaging and secure work environment.