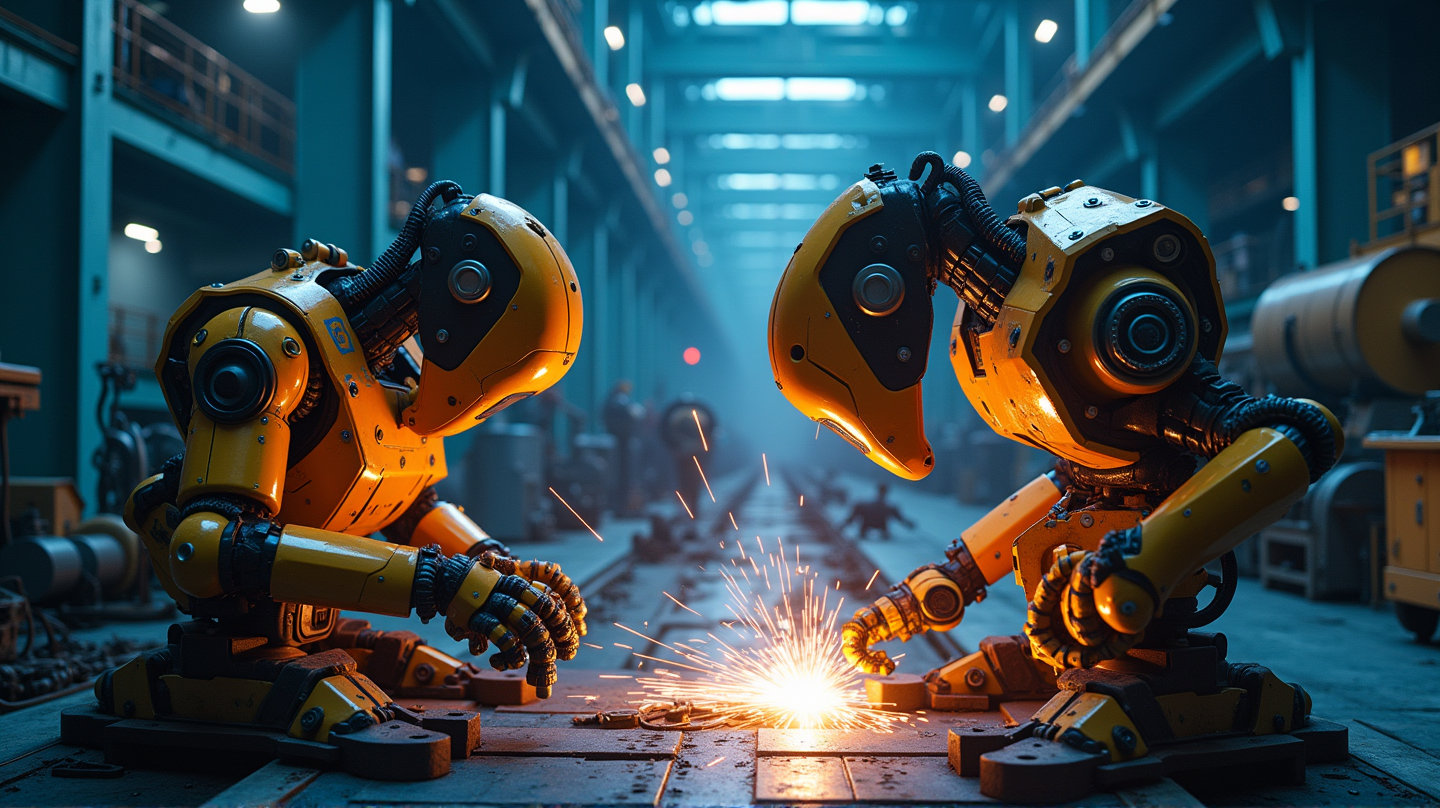

The shipbuilding industry, a cornerstone of technological progress, is currently witnessing a new wave of innovation with the intense rivalry between two Korean giants, HD Hyundai and Hanwha. Their competition, centered around the development of welding robots, marks a transformative leap for the industry. As these corporations invest powerfully in automation, the traditional processes of shipbuilding may soon be a thing of the past.

A Bold New Frontier

HD Hyundai and Hanwha are no strangers to competition, but their latest venture into robotic welding technology elevates the stakes. Their subsidiaries are pouring in resources and energy to perfect this technology, envisioning a future where shipyards are bustling hives of productivity aided by state-of-the-art robots. According to The Korea Times, the development of these robots is not only aiming for precision and efficiency but also catering to the dire need for skilled labor in the industry.

Technological Edge

Welding robots in shipyards are not merely a replacement for human labor. They represent an innovation-driven edge that could redefine ship manufacturing. By incorporating advanced features such as AI-guided precision welding and real-time error detection, these robots promise to significantly slash production time while boosting safety standards on the work floor. This leap could save millions in costs and bring about unprecedented enhancements in quality.

The Global Impact

The ripple effect of this technological race is expected to resonate globally. Countries reliant on shipbuilding can benefit from adopting these innovations, potentially altering economic landscapes with increased production capabilities. As South Korea positions itself at the forefront of this trend, it may set the bar for other nations to follow suit, fostering a global shift towards sustainable and automated shipbuilding methods.

Challenges Ahead

Despite the optimism, the transition to robotic welders is laden with its own set of challenges. Integration of robots into existing shipyard infrastructures demands immense capital, a skilled workforce for robot management, and comprehensive changes in production lines. These hurdles must be overcome to fully tap into the potential of welding robots.

The Road Ahead

As HD Hyundai and Hanwha push the boundaries of technology, their efforts underscore a pivotal movement in the shipbuilding industry. This era of innovation is set to redefine not just how ships are built, but how industries at large can shift towards automation and sustainability. The coming years will indeed be fascinating as we watch these developments unfold.

The age of welding robots is dawning, and it might just reshape the blueprint of shipyards globally.